Students of the International University Travnik created a “Robotic arm”

At the International University Travnik, students of the Faculty of Polytechnic Sciences Travnik, Department of Electrical Engineering, presented the “Robotic arm”. This is a project called “Robotic Arm 387” where students Bekir Fulan, Amil Švago and Džavid Kilim have been working in the past six months and successfully presented.

During the study, students expressed their desire to build a robot, and after consultations and serious planning, they decided to create a “Robotic arm”. The idea of the project was first presented to the Rector of the International University Travnik, Academician, prof. Dr. Ibrahim Jusufranić, who enthusiastically accepted the project and students, provided the necessary material and technical support. During the development of the Robotic arm, students used classrooms, cabinets and labs of the International University Travnik, and support was also provided to the Ministry of Economy of the Central Bosnia Canton. The development of the project was carried out in three phases. The first phase was based on the design and budget. At that stage, students programmed the “Robotic arm” itself through software programs and simulations. In the further work they came to the conclusion that the “Robotic arm” is made of plastic for the sake of ease, precision and material processing itself, and 3D was created in the Solidworks program. They also made simulations of electronics circuits that they manage through the development system “Arduino”.

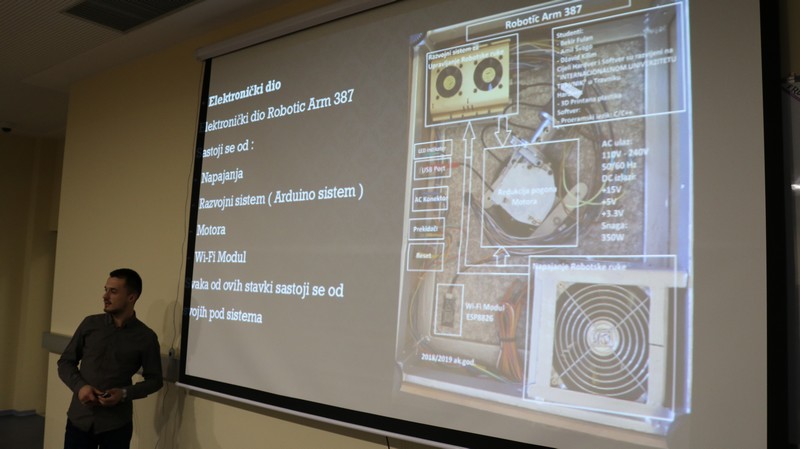

In the second phase, with the help of 3D printers, they made the “Robotic arm” part by piece. The plastic structure itself is 2.5 kg, with 6 steppers and 1 servo engine mounted by the development system. Each engine is on one wrist which means that the arm has 6 degrees of freedom (Movement Angle). The engines are connected to the development system, which consists of power supply, microcontroller board and DRV bridges. In order to get the function and control, it was necessary to connect or solder the engine and development system. After connecting hardware (design and development system), the third phase followed the software part (programming and testing). Students programmed in C ++ programming language.

Full hardware and software were developed at the International University Travnik. A “Robotic arm” can be used in various production units along the conveyor belt.